HPC500 II

HPC500 II

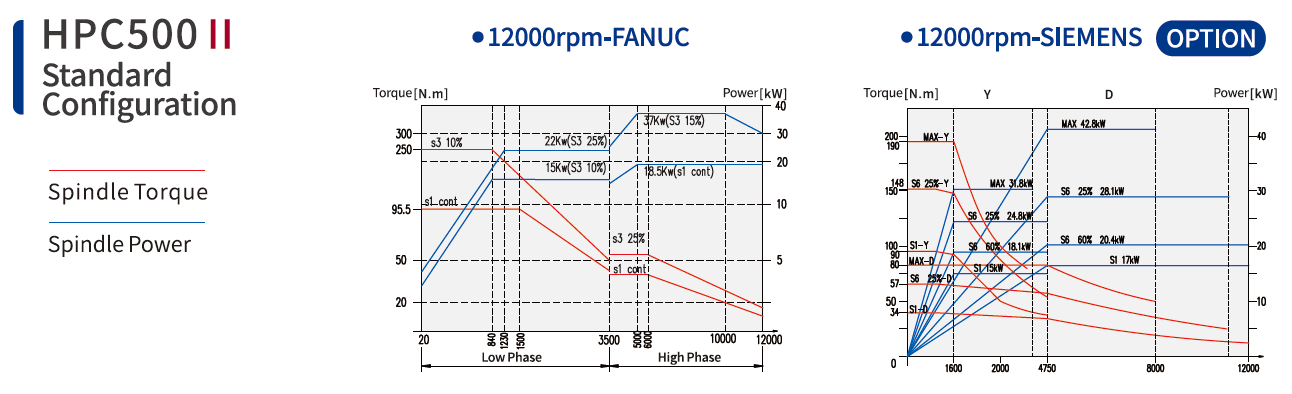

RPM: 12,000 rpm

Power: 18.5/37 kW

Strokes: X: 730 mm Y: 730 mm Z: 800 mm

Max. tool length: 500 mm

Max. tool weight: 12 kg

High Rigid Bed

High load bearing casting bed ensures the stability of processing.

Linear Roller Guide Is Used For X/Y/Z Axis

In order to achieve high-precision and heavy cutting, HPCII series X/Y/Z axis adopts linear roller guide.

X/Y/Z Axis High Speed

Rapid Traverse: 60m/min (X/Y/Z Axis HPC500/600/650II HPC1000).

Built-in Spindle

The built-in spindle provides for fast starting and stopping speed, and greatly reduces the vibration during high-speed operation to ensure the machining accuracy and finish.

Spindle Thermostatic Cooling System

In order to achieve stable spindle accuracy, the coolant cools the spindle bearing and spindle box in a circular motion to reduce inconsistencies in the spindle.

X/Y/Z Axis Standard Hollow Cooling Screw

The coolant passes through the hollow part of the screw rod to effectively restrain the temperature rise and maintain the accuracy.

X/Y/ Axis Shield

The fixed armor protection effectively controls the iron chips and cutting fluid in the fully enclosed processing area, and adapts to the fast and stable operation of moving parts.

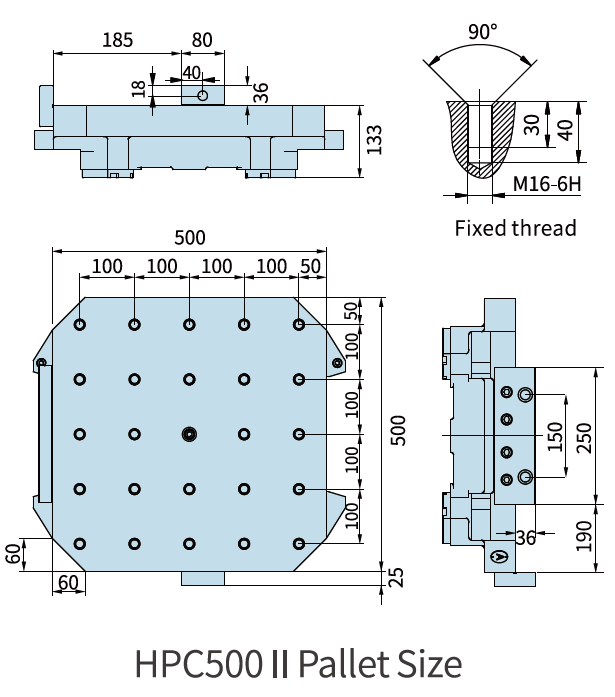

Multiple Workbenches Available

Standard configuration is 1° indexing pallet (except HPC1000/D) NC rotary table is optional.

Double Servo Tool Magazine – ATC

Double servo motors greatly improve tool change efficiency ensures stable tool change.

HPC500 II

| Items | Unit | HPC500 II |

| » Machining Capacity | ||

| X travel | mm | 730 |

| Y travel | mm | 730 |

| Z travel | mm | 800 |

| Spindle center to table surface | mm | 80-810 |

| Spindle nose to table center | mm | 70-870 |

| » Table | ||

| Table size | mm | 500×500 |

| Table indexing | ° | 1° ×360 |

| Table load | kg | 500 |

| » Spindle | ||

| Drive type | Built-in spindle | |

| Spindle power | kW | 18.5/37 |

| Spindle speed | r/min | 12000 |

| Spindle torque | Nm | 95.5/250 |

| Spindle taper | ISO7:24NO.40 | |

| Pull stud | P40T-I-MAS403 | |

| » Feed Rate | ||

| Rapid traverse (X/Y/Z) | m/min | 60 |

| Cutting feedrate (X/Y/Z) | m/min | 60 |

| Pallet 90° indexing time | s | 1.4 |

| » APC | ||

| Pallet change type | Direct rotary type | |

| Pallet change time | 9 | |

| » Tool Magazine | ||

| Tool magazine capacity | T | 40 |

| Tool selection mode | Shortest path | |

| Tool shank type | BT40 | |

| Max. tool length | mm | 500 |

| Max. tool dia. (Adjacent Vacant) | mm | Φ80/Φ160 |

| Max. tool weight | kg | 12 |

| Tool change time (T-T) | s | 1.5 |

| » Other | ||

| Power capacity | kVA | 64 |

| Machine weight | t | 10 |

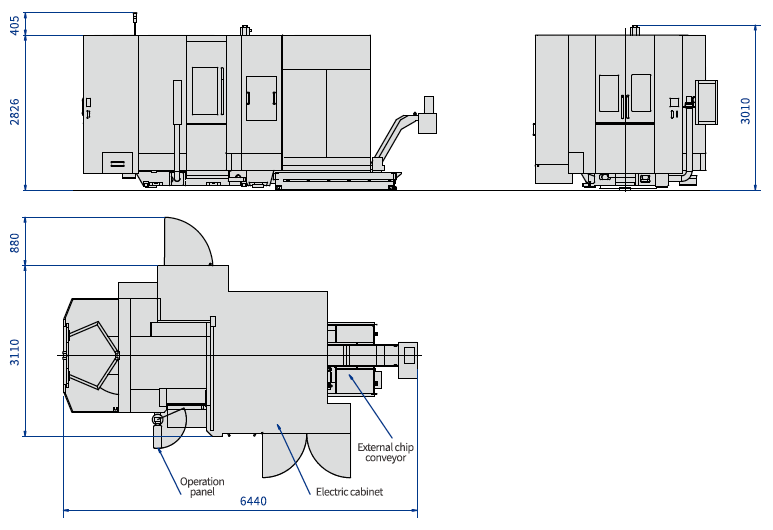

| Machine size (L×W×H) | cm | 644×310×300 |

Standard Configuration

- Controller:FANUC 0i MF PLUS

- 40T ATC (HPC800II 60T)

- 1° indexing pallet (HPC500II, HPC600II, HPC650II, HPC800II)

- NC table 0.001° indexing (HPC1000/D)

- APC (HPC1000/D is single pallet)

- Full enclosure with top cover

- Guide rail protection External chain type chip conveyor

- Cutting cooling

- Spindle oil chiller

- Screw cooling oil temperature control device

- Spindle blowing

- Automatic power-off device

- Self diagnosis function

- 3-color signal lamp

- Standard accessories

Machine Size