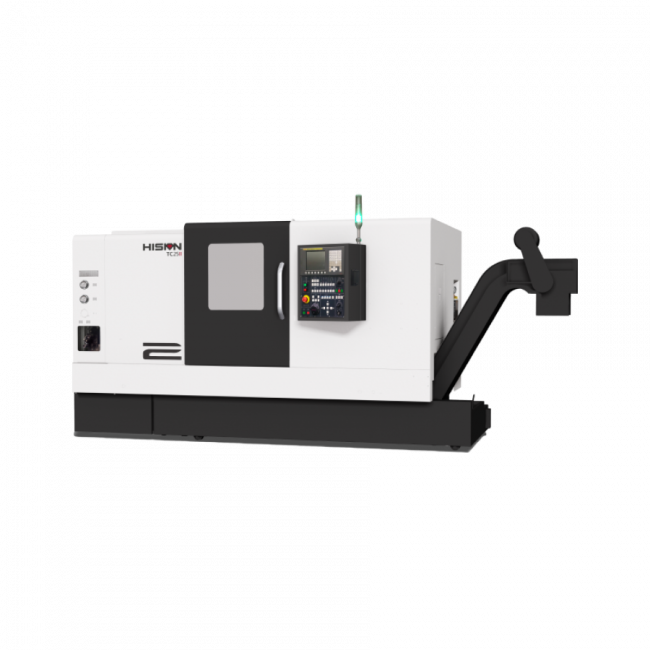

TC25 II x 1000

TC II series CNC lathes are dedicated to the functions of high rigidity and high stability, aiming to create a cost-effective classic product. This series is a hard rail machine tool, equipped with mechanical spindle and hydraulic turret, can cover φ 400-φ 800 processing diameter specifications, widely used in automotive parts and general industry. Especially suitable for heavy duty cutting of large diameter and long shaft products.

TC series CNC lathes adopt 45° integral casting bed structure and hardened grinding guide rail form. All castings are optimized by finite element analysis to ensure high precision and high stability of the machine tool. The automatic interface and modular protection design are ideal for turnkey and automation projects.

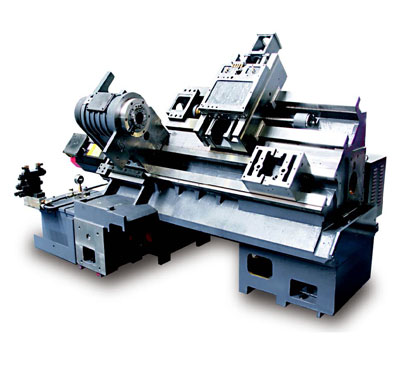

45° Integral Inclined Bed

The 45° integral inclined bed realizes high rigidity and stability along with a simplified chip removal process. The guide rail has been hardened and finely ground, and the wear-resistant soft belt is affixed to the sliding surface.

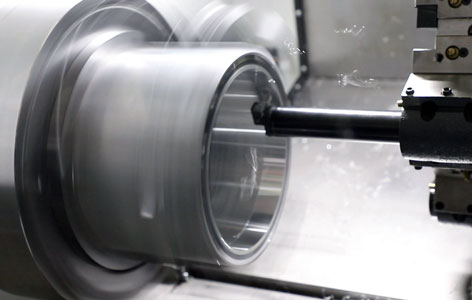

High Rigidity Spindle

The spindle itself adopts imported bearings along with support at two points. The front end adopts double row cylindrical roller bearings and high-speed thrust angular contact bearings. The rear end adopts double row cylindrical roller bearings providing strong rigidity, making it suitable for heavy duty and precision cutting.

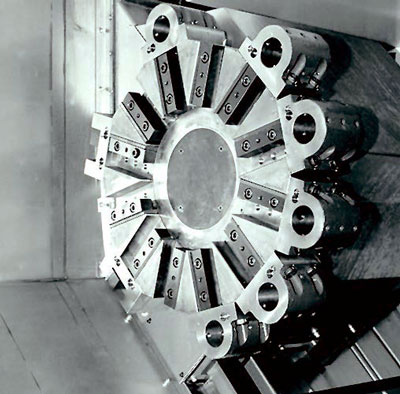

Customized Cutter Head

(optional power cutter tower)

TC series comes standard with a 12-station hydraulic turret, suitable for heavy cutting. A customizable cutter head allows for enhanced cutter block rigidity while minimizing tool interference.

Hydraulic Tailstock

The tailstock movement is saddle driven with an additional telescopic sleeve, which utilizes programmable hydraulic pressure. The split tailstock structure allows for convenient and reliable adjustments.

Automatic Protection Module

An available automatic door with skylight modular design provides for additional convenience during operation.

TC25 II x 1000

| Items | Unit | TC25 II X 1000 |

| » Capacity | ||

| Swing over bed dia. | mm | Φ560 |

| Swing over saddle | mm | Φ320 |

| Max. turning dia. | mm | Φ400 |

| Max. turning length | mm | 1000 (≤Φ320) |

| Chuck size | inch | 8 |

| Bar capacity dia. | mm | Φ50 (OptΦ65) |

| » Travel / Rapid | ||

| X/Z travel | mm | 210/1050 |

| X/Z rapid traverse | m/min | 24/30 |

| » Spindle | ||

| Spindle type | - | Belt spindle |

| Max. spindle speed | rpm | 4500 |

| Main spindle motor power | kW | 11/15 |

| Max. spindle torque | Nm | 140/250 |

| Spindle nose | - | A2-6 |

| Spindle bearing diameter (Front) | mm | Φ100 |

| » Turret | ||

| Turret type | - | Hydraulic |

| Turret capacity | - | 12 |

| OD tool size | mm | 25×25 |

| Boring bar dia. | mm | Φ40 |

| Tool changing time (including clamp) | s | 0.55 |

| » Tailstock | ||

| Tailstock type | - | Hydraulic |

| Tailstock travel | mm | 730 |

| Quill dia. | mm | Φ100 |

| Quill travel | mm | 120 |

| Quill bore taper | - | MT NO.4 (Opt Dead MT NO.4) |

| » Motor | ||

| X/Z motor power | kW | 1.8/1.8 |

| X/Z motor torque | Nm | 11/11 |

| » Others | ||

| Power capacity | kVA | 25 |

| Coolant tank | L | 200 |

| Controller | - | FANUC 0I-TF |

| Machine size (LxWxH) (without conveyor) | cm | 420x205x190 |

| Machine weight | t | 5 |

Standard Configuration

- Controller: Fanuc 0i / SIEMENS 828D

- Hydraulic and lubrication system

- Cutting cooling

- Full enclosure

- 12T hydraulic turret station

- Soild hydraulic chuck

- Tool holder

- Tailstock with live quill

- External chain type chip conveyor(side)

- Standard accessories

- Ground installation

- Common maintenance tools

- Soft jaw

- 3-color signal lamp, working light

- Foot switch

- Trolley