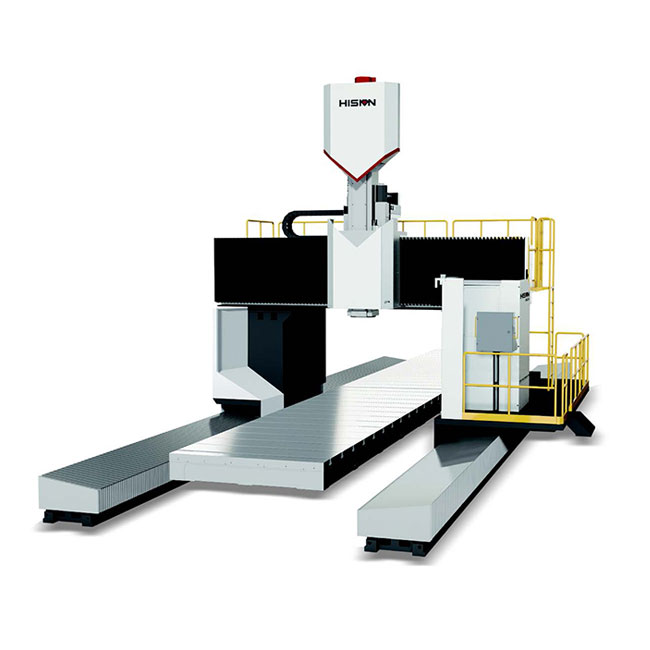

GNUM Series

The product inherits the characteristics of traditional gantry machine tools, such as strong rigidity, symmetrical structure and high stability. Through finite element analysis, it optimizes the structure of basic components, improves the dynamic performance of the product, and obtains the perfect combination of high power, high torque, high efficiency and high-precision processing. It is applicable to large and heavy processing fields such as ships, metallurgy, petrochemical industry, mining machinery, electric power and energy, plastic machinery, engineering machinery, heavy industry machinery, etc.

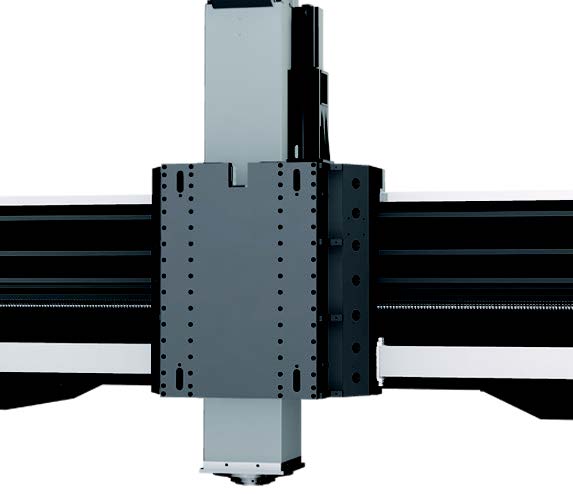

High Rigid Square Ram

An all-inclusive four-sided constrained guide rail provides a square ram along with a double hydraulic cylinder for balance. This system provides strong rigidity cutting ability and accuracy.

Self-Made Powerful Spindle

This powerful spindle includes a double row cylindrical roller bearing, which is built into the spindle, providing high rigidity and torque.

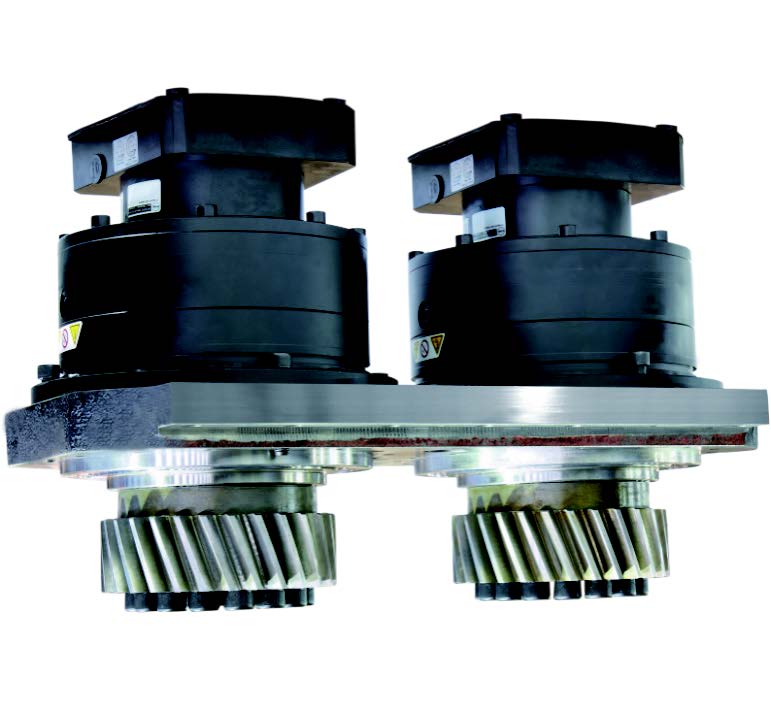

Double Motor Anti-Backlash Transmission Mechanism

The moving column series double motor includes a clearance eliminating transmission mechanism which meets the requirements of high-speed and precision linkage cutting.

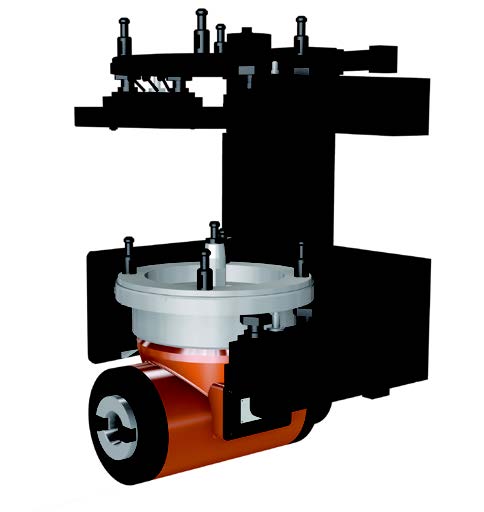

Column Rotating Head Magazine

A compact structure, realizes automatic head changes, which reduces processing time and improving production efficiency.

Vertical and Horizontal Tool Magazine

Accurate positioning allows for effective shortening of processing time.

GNUM 40x90 - 50x130

| Items | Unit | GNU40M×90 | GNU40M×110 | GNU50M×100 | GNU50M×130 |

| » Machining Capacity | |||||

| X travel | mm | 9000 | 11000 | 10000 | 13000 |

| Y travel | mm | 4400+150 (tool change) | 4400+150 (tool change) | 5400+150 (tool change) | 5400+150 (tool change) |

| Z travel | mm | 1250 | 1250 | 1250 | 1250 |

| Distance between columns | mm | 4100 | 4100 | 5100 | 5100 |

| Spindle nose to table surface | mm | 150-1400 | 150-1400 | 150-1400 | 150-1400 |

| » Table | |||||

| Table size | mm | 3000×8000 | 3000×10000 | 4000×9000 | 4000×12000 |

| Table loading | t/m² | 5 | 5 | 5 | 5 |

| T slot size | mm | 28×250 (Y direction) | 28×250 (Y direction) | 28×250 (Y direction) | 28×250 (Y direction) |

| » Feed Rate | |||||

| Cutting feedrate (X/Y/Z) | m/min | 6/6/6 | 6/6/6 | 6/6/6 | 6/6/6 |

| Rapid traverse (X/Y/Z) | m/min | 10/15/10 | 10/15/10 | 10/10/10 | 10/10/10 |

| » Spindle | |||||

| Max. Spindle speed | rpm | 3500 | 3500 | 3500 | 3500 |

| Spindle power | kW | 30/37 | 30/37 | 30/37 | 30/37 |

| Spindle torque | N.m | 1860/2300 | 1860/2300 | 1860/2300 | 1860/2300 |

| Spindle taper | BT50 | BT50 | BT50 | BT50 | |

| Ram section | mm | 450×450 | 450×450 | 450×450 | 450×450 |

| » Tool Magazine (Option) | |||||

| Vertical tool magazine capacity | T | 24/40 | 24/40 | 24/40 | 24/40 |

| Max. tool dia (Adjacent Vacant) | mm | Φ110/Φ220 | Φ110/Φ220 | Φ110/Φ220 | Φ110/Φ220 |

| Max. tool length | mm | 400 | 400 | 400 | 400 |

| Max. tool weight | kg | 20 | 20 | 20 | 20 |

| V&H tool magazine capacity | T | 40/60 | 40/60 | 40/60 | 40/60 |

| Max. tool dia. (Adjacent Vacant) | mm | Φ125/Φ250 | φ125/φ250 | φ125/φ250 | φ125/φ250 |

| Max. tool length | mm | 400 | 400 | 400 | 400 |

| Max. tool weight | kg | 25 | 25 | 25 | 25 |

| » Other | |||||

| Power capacity | kVA | 85 | 85 | 85 | 85 |

| Machine weight | t | 103 | 120 | 119 | 139 |

| Machine size (L×W×H) | cm | 1800×1000×730 | 2000×1000×730 | 1900×1100×730 | 2200×1100×730 |